Ultracentrifugation Tube, Cone-Top, PA, 11x25mm, 50 pieces

S9013

Product Details

Description

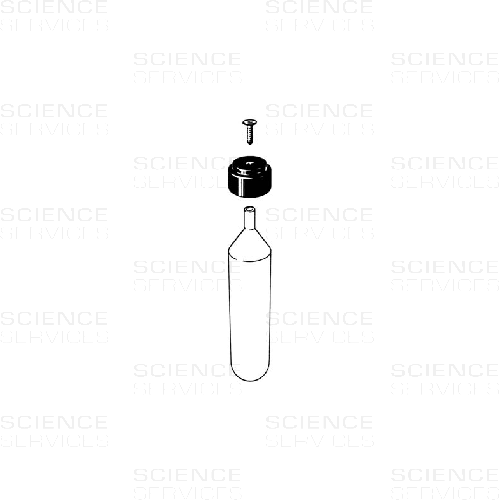

Cone-Top Tubes

The Science Services Cone-Top system positions a short column tube at the bottom of your rotor hole resulting in a k-factor reduction and increased pelleting efficiency of your rotor (1). Shorter path lengths can reduce run times. These reduced volume tubes offer added flexibility with your present rotors with no need für speed reductions or oil overlays to fill open-top tubes to the required levels. Because the tubes are filled and sealed, gradient concentrations do not change by evaporation as may occur with partially-filled thick wall tubes.

The patented Cone-Top seal System fixes the crown to the top of the tube and maintains the conical tube shape during centrifugation (2). In swinging bucket rotors the Cone-Top system provides a secondary seal and increased protection when separating hazardous materials. Cone-Top tubes may be resealed and offer the advantage of multiple runs with the same tube. Use of Science Services Easy-Out fractionation devices allow direct connection to the top of the tube. The cone top provides a uniform configuration for efficient sample removal.

With the Cone-Top System the use of heat arrd expensive heat sealing stations is eliminated--the seal is made with a simple hex key wrench. Cone-Top polyallomer tubes can be autoclaved, punctured and sliced. Find your rotor in the chart on the next page. You will need one crown and one plug for each hole you intend to use in your rotor. The plug is tightened with wrench PN 4088.

How to Use:

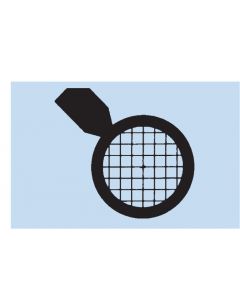

After the Cone-Top tube is filled a crown is placed on the stem of the tube, a plug is screwed into the stem and hand-tightened with the wrench. As the plug is screwed in, it forms a thread in the stem of the tube providing a reliable compression seal. After centrifugation, the tube assembly can be pulled form the rotor with hemostats and the plug unscrewed. The tube can be reused by again screwing in the plug. Noryl crowns, stainless steel plugs and polyallomer tubes can be sterilized by autoclaving, ethylone oxide gas or immersion in aqueous solutions of 70% ethanol, 70% ispropanol or 10% hydrogen peroxide.

(1) Rickwood, D., editor, Centrifugation (2nd Edition), Oxford: IRL Press, Ltd., 1986.

(2) U.S. Patent 4,690,670 and UK Patent GB 2185245 apply.

More Information

| Type |

Cone-Top

|

|---|---|

| Material |

Polyallomer

|

| Packing Unit | 50 pieces |

| Tube Diameter |

11mm

|

| Volume | 1,5ml |

| Manufacturer |

Seton

|

Related products

-

€47.00 €55.93Art.Nr: S4246

- Noryl

- 100 KRPM Max

- Use Tubes: 9011, 9012

- For Rotors: TLS55, S55-S, TH660, TFT80.4

€47.00 €55.93 -

€39.40 €46.89Art.Nr: S4088This hex key with molded plastic handle is used to tighten the 4073/4075 plugs.€39.40 €46.89

-

Art.Nr: S4116This easy-to-use device duts offthe Beckman heat-sealed stem or the DuPont crimp-sealed stem while the tube remains in the vertical position.

-

€183.80 €218.72Art.Nr: S4131

Tube racks are made of white Delrin and are designed to preciscely fit Science Service, Seton, Beckman and DuPont/Kontron ultracentrifuge tubes.

€183.80 €218.72 -

€85.30 €101.51Art.Nr: S4195The special blade assembly has a large loop for use with all microtubes up to 1.5ml. lt will cut all brands and materials of tubes and pipette tips including PA, PP, high and low density PE.€85.30 €101.51