TMC CleanBench - Vibration Isolation Table

Product Details

Description

The TMC CleanBench™ combines the latest, patent pending improvements to our table tops with our superior Gimbal Piston™ air vibration isolation system.

The TMC CleanBench™ Table is offered in 3 standard configurations above:

2 basic sizes and a configuration recommended for Ultramicrotomy and Microscopy.

Further sizes, accessories and information are available in our Datasheet in order to fulfill customer-specific requirements. Our technical support is happy to assist you customizing your table: tech@scienceservices.de

TMC CleanBench™ Features

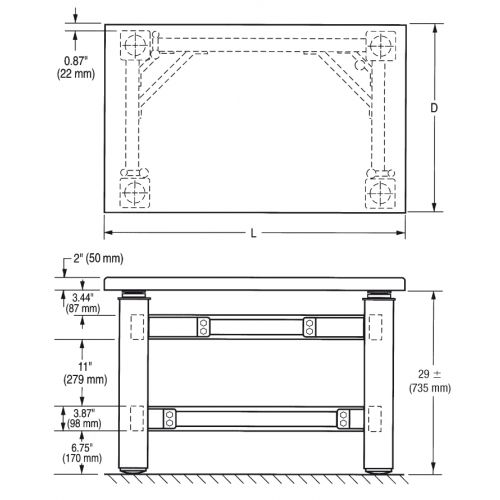

- New, low-profile top for superior damping, stiffness and flatness in a stainless steel shell

- Unique new slim table top design (patent pending) for highest product quality

- Greater stability due to lower center-of-mass and higher density

- Guided thread lead-ins for screw alignment with tapped holes

- Optimized ergonomics due to slim design (50mm

Dimensions

Specifications

| Isolator natural frequency: | High Input: Vertical = 1.2 Hz Horizontal = 1.0 Hz Low Input: Vertical = 1.5 - 2.0 Hz Horizontal = 1.2 - 1.7 Hz |

| Isolation efficiency @ 5 Hz: | Vertical = 70 - 85% Horizontal = 75 - 90% |

| Isolation efficiency @ 10 Hz: | Vertical = 90 - 97% Horizontal = 90 - 97% |

| Recommended load capacity: | 160kg (350 lb) |

| Finish: | Medium texture black powder coat frame, stainless steel top |

| Facilities required: | 5.4 bar (80psi) air or nitrogen, quick connector for 6mm OD hose |

| Shipping weight: | Approx. 272kg (600 lb) |

| Height control valves: | Repeatability standard valve: +/- 1.3mm (0.050 inch) Precision valve: +/- 0.13mm (0.005 inch) |

Select the CleanBench top

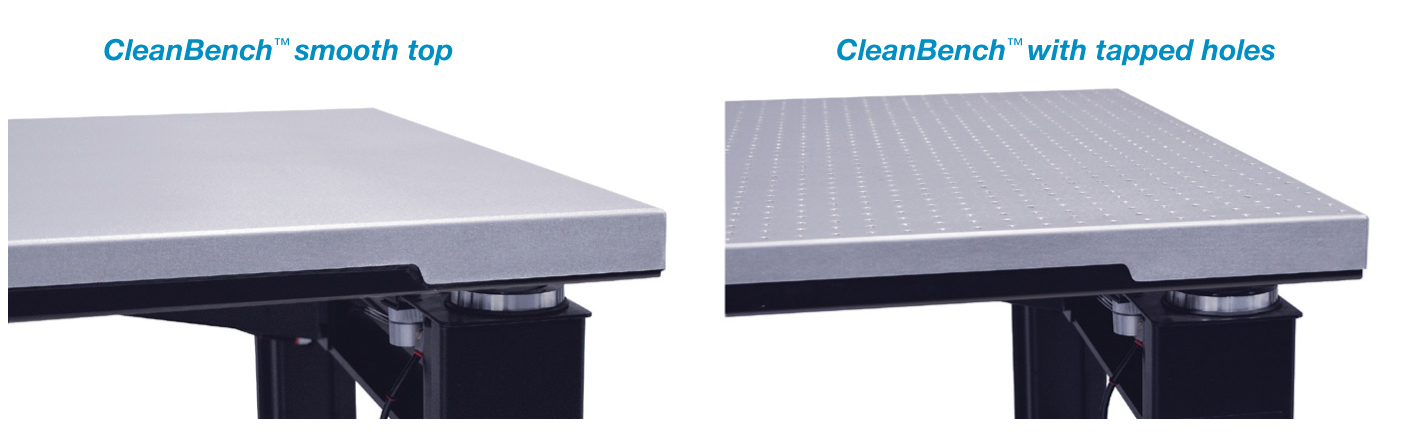

CleanBench™ smooth top

The smooth “laminated top” construction has been developed for small, desk-style vibration isolation tables. The 50mm (2inch) thick platform incorporate sandwiched layers of steel and core material rigid epoxy bonded into a seamless, stainless steel shell with rounded edges. Ideal for use that does not require tapped holes.

CleanBench™ with tapped top

A grid of imperial (1/4-20 on 1-inch) or metric (M6 on 25mm) tapped holes enables the user to bolt-down the payload or positioning equipment. Different to the old version the platform stays thin (50mm) to prevent raising the center-of-mass, reducing stability and to improve ergonomics. TMC’s proprietary method of forming the tapped holes results in beveled lead-ins, which eases thread engagement and allows for a full three threads.

See technical data sheet for detailed information.