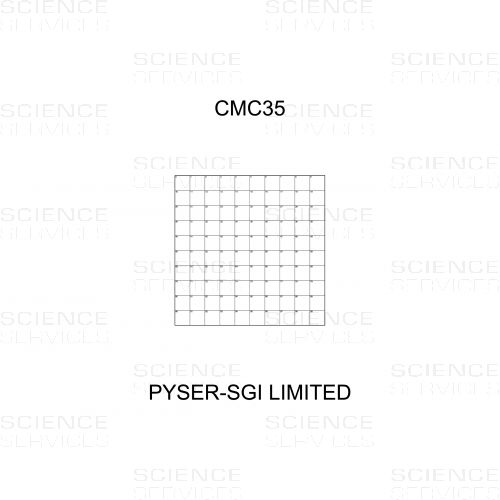

Correlative Microscopy Coverslips® - CMC35, 25 pieces

PY01ACMC35

Product Details

Description

Reticle film has been thoroughly tested with cell culture

- Good growth of cell culture (equivalent to conventional media)

- Good adhesion to the substrate without cell polylysine

Physical and chemical qualities

- Resistant to normal chemicals used in electron microscopy

- No oxygen retention, compatible resin LR White

- Good optical quality in brightfield & UV fluorescence

- Excellent transparency

- Does not deform at temperatures (positive 100C and negative liquid N2)

- Rigid, does not float in the middle of culture

- Easy to handle and cut with a knife or micro-punch

- Simple sterilisation using alcohol or UV

- Detaches easily from resin after polymerisation

- Low cost

Applications: light microscopy, fluorescence, scanning electron microscopy (SEM), transmission electron microscopy (TEM), high-pressure cryofixation, .....

Products developed in conjunction with Nacer Benmeradi, PhD of CNRS Toulouse and Delta Microscopies, France.

All Correlative Microscopy Coverslips® are produced on a polyester based film, 0,18mm thick, 22x22mm. 25pcs per box.

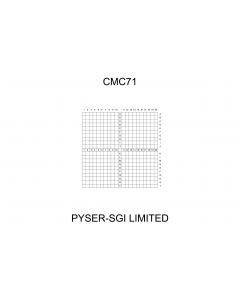

Other patterns, grid sizes and film sizes are available to special order.

Useful information about the Correlative Microscopy Coverslips and their use:

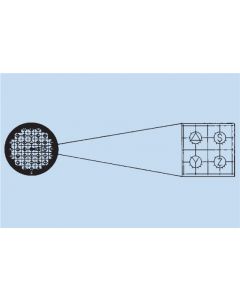

1. Use with Fluorescent Microscopes. These new correlative microscopy coverslips (CMC's) are not designed to replace the glass or quartz coverslips, which have superior optical properties, and so are far better for fluorescent microscopy. The CMC's are designed to satisfy the needs of correlative microscopy where an initial, general analysis is performed using light or fluorescent microscopy and then the specimen is further processed for analysis by SEM, TEM or cryofixation.

If you need to perform detailed analysis using fluorescent microscopy then the CMC's are not the solution. If however you want to perform a comprehensive analysis using different analysis techniques then the CMC's are the only solution. The key advantage of the CMC's is that they are made on special film that can be cut or punched (for cryo applications), something that is not possible with glass coverslips. The grid image is also transferred to any embedded specimen making cell location far easier.

2. Best Types of Resin to Use. Because this is new technology it often requires a change in the customers preparation method. The method that the customer has traditionally used for glass coverslips may not be suitable for these film ones. There will be a website up and running soon (www.correlative-microscopy-coverslips.com) that will provide all technical information and blogs so that customers can share experiences and contribute to method development.

The key thing to successful use of these CMC's seems to be the type of resin and the preparation. We have already mentioned about the need to ensure a hermetic seal between the Beem capsule and the CMC film. The preparation works perfectly with low viscosity epoxy resins (eg Spurr, EPON). Sufficient polymerisation is obtained in 24 hours at 60C - it does not normally require 48 hours.

We are gathering information all the time from users as we develop the preparation methods, so all feedback is very useful. Please use our technical contact to keep us updated unformally - we will communicate all points with the manufacturer.

3. Film Type. The CMC's are made on a special polyester base film which is 0.18mm thick. There is no absolute tolerance specified on the thickness of the film.

More Information

| Form |

square

|

|---|---|

| Material |

Polyester

|

| Packing Unit | 25 pieces |

| Size | 22x22mm |

| Surface Covered | 100mm² |

| Thickness | 0,18mm |

| Unit Size of each square | 0,5mm² |

| Manufacturer |

Graticules Optics

|