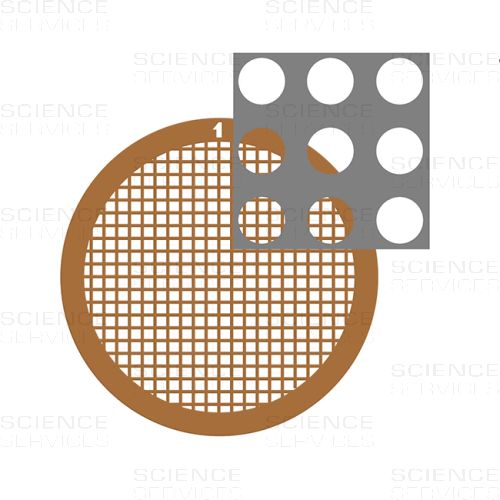

C-flat™ thick, 2,0µm Hole Size, 1,0µm Hole Spacing, Cu

Product Details

Description

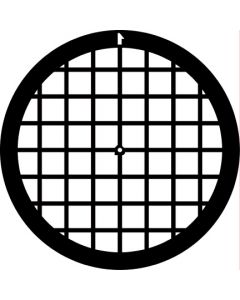

C-flat™ is a holey carbon film supported by a standard TEM grid. C-flat™ products are fully specified by 4 parameters: the hole diameter and pitch of the holey carbon film and the material type and mesh size of the TEM grid.

The C-flat™ Advantage

Made with patent pending technology, C-flat™ provides an ultra-flat surface that results in better particle dispersion and more uniform ice thickness. Patterning is done using deep-UV projection lithography, ensuring the most accurate and consistent hole shapes and sizes down to submicron features. The precise methods by which C-flat™ is manufactured elminate artifacts such as excess carbon and edges around holes.

C-flat™ is affordable

C-flat™ is available in 25, 50, and 100 packs at a per-grid price less than competing products.

Applications

C-flat™ holey carbon grids provide the ideal specimen support to achieve high resolution data in cryo-TEM making them an ideal choice for single particle analysis, cryo electron tomography and automated TEM analysis.

Cryo-electron tomography (cryoET) and Single Particle Analysis ( SPA ):

Numerous researchers have reported that the ultra-flat surface of C-flat™ leads to even ice thickness and uniform particle distribution within the hole areas. This optimal particle distribution results in superior data being collected as compared with other holey support films. 2µm hole sizes are standard but custom hole sizes are available so C-flat™ can accommodate the common magnifications used for quantitative TEM analysis.

Automated TEM:

C-flat™ provides a regular array of analysis sites compatible with automated data collection software such as Leginon. This compatibility, in combination with the more uniform ice thickness and particle distribution reported by numerous researchers, results in more high-quality target sites per grid.

<< For detailed information see datasheet >>

Publications

Quispe J, Damiano J, Mick SE, Nackashi DP, Fellmann D, Ajero TG, Carragher B, Potter CS, (2007). An improved holey carbon film for cryo-electron microscopy. Microscopy and microanalysis, 13(5), 365-371.

A. Cheng, D. Fellmann, J. Pulokas, C.S. Potter, B. Carragher (2006). Does contamination buildup limit through put for automated cryoEM? Journal of Structural Biology, Volume 154, Issue 3, 303-311.

S.M. Stagg, G.C. Lander, J. Pulokas, D. Fellmann, A. Cheng, J.D. Quispe, S.P. Mallick, R.M. Avila, B. Carragher, C.S. Potter (2006). Automated cryoEM data acquisition and analysis of 284 742 particles of GroEL. Journal of Structural Biology, Available online 22 May 2006.

<< For detailed information see datasheet >>

More Information

| Hole Spacing |

1,0µm

|

|---|---|

| Coating |

Holey Carbon

|

| Film Thickness | approx. 20nm |

| Grid Size | 3,05mm |

| Hole Shape |

round

|

| Hole Size | 2,0µm |

| Material |

Copper

|

| Material Symbol | Cu |

| Mesh Style |

square

|

| Manufacturer |

C-flat

|