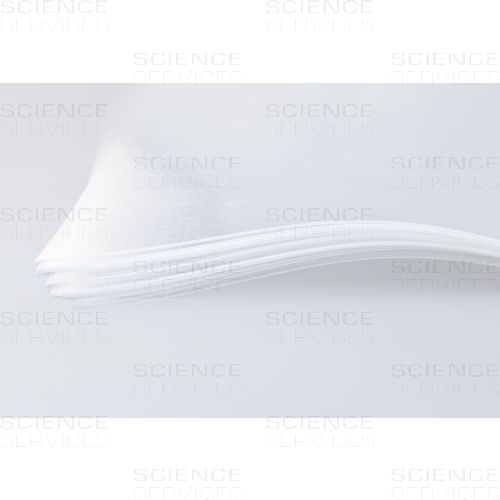

ACLAR® Fluoropolymer-Film, 210x297mm (DIN A4), 51µm thick (2mil), 10 pieces

A50426-10

Product Details

Description

ACLAR® is made from fluorinated-chlorinated resins. There are four basic film types–the homopolymer ACLAR® Rx Series, the new ACLAR® UltRx and the discontinued copolymers ACLAR® 22A and 33C (Honeywell). The chemical make-up of all ACLAR® products provide an exceptional moisture barrier. ACLAR® is crystal clear, biochemically inert, highly resistant to most chemicals and sterilizable by heat or radiation. ACLAR® is used widely in pharmaceutical, medical, sensitive electronics and military packaging.

ACLAR® UltRx is a PCTFE homopolymer film. It offers an outstanding moisture barrier, excellent chemical resistance and small dimensional change (<6%). It is crystal clear, biochemically inert, plasticizer and stabilizer free. It is successfully used to grow cells, perform high-pressure-freezing (HPF) and for embedding.

Features:

- Crystal clear, high UV transparency– ideal for use in UV curing of embedding resin in microscopy.

- Chemically stable and biochemical\y inert– the product of choice for growing cell cultures.

- Low dielectric constant, high electric strength and dissipation factor– offers excellent cell attachment even through lengthy processing procedures.

- Low surface energy–and separates easily from epoxy.

- Exhibits no detectable autofluorescence– ideal for fluorescent microscopy.

- A non-flammable, non-aging co-polymer–

which is suited for sterilization by heat or UV. - Crystalline melting point is 211°C (403°F)– stable in the SEM.

- Flexible and soft– can be sectioned without damage to the ultramicrotome knives.

ACLAR® film is now available in 2 mil (51µm) thickness and it is offered in DIN A4 (210x297mm) sheet form with package quantities of 10 or 25.

ACLAR® Physical Data Sheet

(These are typical values for 2.00mil PCTFE homopolymer and are not to be interpreted as product specifications):

| Properties@ 73°F ~50% RH | English | Metric | Test Method |

| Gravity Specific | 2.11 | ASTM D1505 | |

| Yield |

6,567 in2/lb. | 9.34m2/kg | |

| Haze | <1% | ASTM D1003 | |

| Crystalline Melting Point | 412°F | 211°C | ASTM D4591 |

| Dimensional Stability, 10 min @ 300°F -MD -TD |

<+6% <6% |

ASTM D1204 | |

| Water Vapor Transmission Rate @ 100°F (37.8°C)/ 100% RH |

0.0077 gm/100 in2/day | 0.119 g/m2/day | ASTM F1249 |

| Flammability | Nonflammable | ||

| Surface Tension |

>42 dynes/cm |

ASTD D2683 | |

ACLAR® Chemical Resistance (typical)

| Chemicals | Average Weight Increase | Visible Effect on Sample |

| Acetone | 0.5% | None |

| Butyl Alcohol | - | None |

| Carbon Tetrachloride | 1.6% | Slightly flexible |

| 1,2-Dichloroethane | 0.03% | None |

| Ethyl Acetate | 6.0% | Very flexible |

| Ethyl Alcohol | None | None |

| Ethyl Ether | 5.2% | Very flexible |

| Ethylene Oxide | 4.0% | Very flexible |

| Formic Acid | None | None |

| Gasoline | None | None |

| All Acids (HCl, H2SO4..) | None | None |

| Methanol | None | None |

| Propylene Oxide | - | None |

| Toluene | 1.1 | Slightly flexible |

| Osmium Tetroxide | None | None |

| Plastisolve | - | None |

More Information

| Dimensions | 210x297mm (DIN A4) |

|---|---|

| Packing Unit | 10 pieces |

| Manufacturer |

ACLAR

|